All of these bilge separators are treatment systems that combine a gravity oil water separator ows or centrifuge with one or more additional unit.

Bilge water oil separator filter.

Because bilgewater cannot be directly pumped out into the sea it is first passed through an oily water separator where the level of suspended oil particles in the mixture is significantly brought down.

It has maintained the bilge since.

Based in the uk wave international designs and manufactures a complete range of marine systems such as bilge filters and grey water systems to suit a variety of leisure and commercial applications.

Vetus separator collects and retains oil and grease from the bilge water before it is passed back out to sea.

Rugged construction of the oil water separator and its lack of moving parts make maintenance minimal.

After installation i turned it on and within an hour and a half the sheen was gone and i could see the bottom of the bilge.

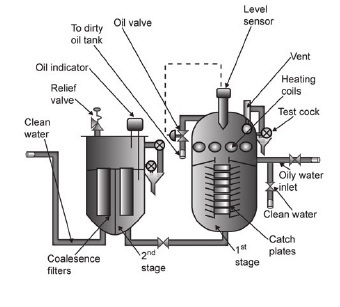

Two stage oily water separator a complete oily water separator and filter unit for 15 ppm parts per million purity is shown in the figure above.

Excellent product and service it was good to do business with.

The filter element is replaceable and has a capacity of 0 7 pounds which is the average quantity of oil in 211 gallons of bilge water.

The bilge filter tbf is simple flow thru filter system that works with any bilge pump and removes oils from your bilge water.

For this reason bilge wells are periodically emptied by pumping out the bilge with the help of bilge pumps.

The bilge filter system uses the same filter media that we use on the brute b uscg abs bv certified oily water separators.

Our products are supplied worldwide through a network of focused distributors which is expanding all the time.

This vetus separator collects and retains oil and grease from the bilge water.

The bilge filter tbf is simple flow thru filter system that works with any bilge pump and removes oils from your bilge water.

Prior to installing the bilge licker i had a pretty thick sheen of oil in my bilge.

Filter assembly and replacement elements are designed to filter oils out of bilge water.

Hence marpol stipulates that the engine room bilges must only be pumped out through suitable oil water processing equipment bilge oil separator or retained for discharge ashore.

Installation was simple and easy to do.

Than one hundred bilge separators have been certified by the u s.

It will remove 95 of oil in the bilge water with a maximum contamination level of 300 mg l p p m.

The filter element is replaceable and has a capacity of 320 grams which is the average quantity of oil in 8 000 litres of bilge water.